Flex-E DDACommercial Lift

Flexible design with ultra-low pit & headroom.

Rated load

Up to 400kg and more

Capacity

Up to 5 persons

Drive system

VVVF Electric Screw driven

Power supply

220-230V, 1phase

Travel height

Up to 4 metres

Landings

up to 6

Door Clearance

940 x 2000 (width x height, mm)

Door configurations

Right or left swing, up to 3 doors per landing

Certification

For BCA E3.1, E3.6 and AS1735.12 – 1999 for PCA compliance

Flex-E Lift is an electric VVVF controlled vertical commercial lift assembled using high-quality European materials and technology.

Designed to be used within commercial situations requiring a wheelchair or limited mobility access up to 4m in height.

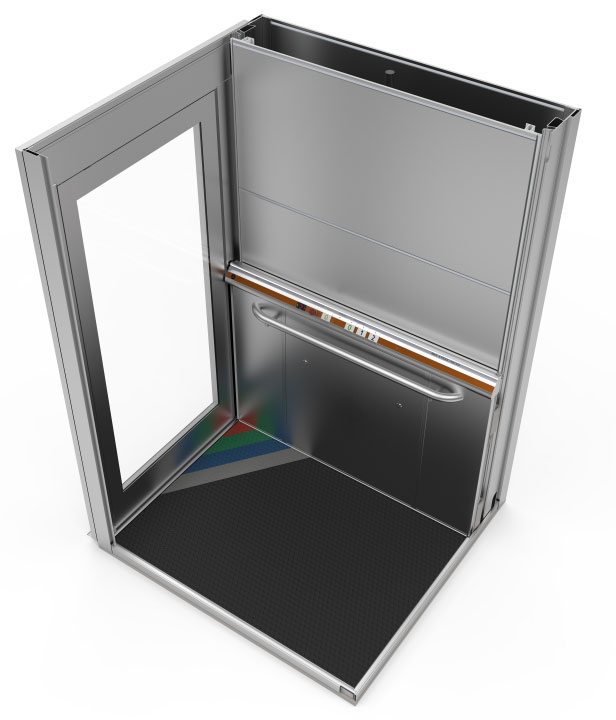

The advantage of the Flex-E Lift is that it can be installed into an existing masonry shaft or with its own proprietary aluminium shaft. The lightweight shaft is able to be constructed of multi-layered steel sandwich panels or various types of glass panels to provide a panoramic feature.

This type of construction is modern, aesthetically pleasing and gives a clear view of the surroundings.

A maximum of three doors may be installed on each floor with either left or right swing and also the selection of self-closing doors or optional automatic powered doors.

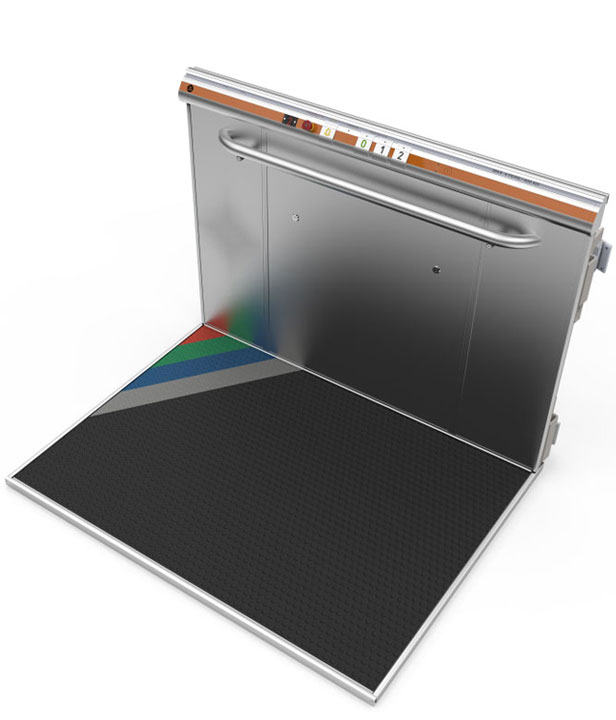

A LED-backlit control panel with a handrail below contains large, easy-to-push buttons with tactile braille symbols. The buttons are at a convenient height for accessing from a sitting or standing position.

For additional safety, in the case of a power outage, the lift will automatically lower to the closest floor and open the door using a backup battery.

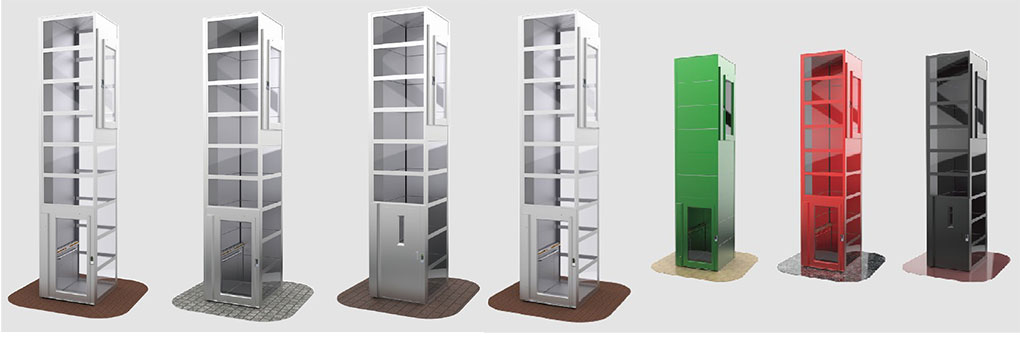

Flex-E lift is highly customizable via a wide variety of colours, door types/positions as well as other value-adding features such as voice annunciation of floors.

Why choose Flex-e DDA?

- Flexible design

- Low space requirements

- High level of security

- Power-saving technologies

- Smart digital control system

- Fast and intuitive installation

- Exterior design options

- Durable screw drive

- Wide range of options and accessories

“Flex-E DDA Lift will enhance your building’s accessibility

& make life easy and respectable for those with limited mobility”

Design

The drive of Flex-e Lift DDA is based on a spindle with machined threaded rod. The motor is mounted on the plaform itself and rotates the spindle, which moves along the stationary threaded rod thereby smoothly lifting the platform.The spindle/screw features a self-locking gear for additional safety.

The Omron VVVF controller is able to smoothly and precisely control the motor to millimeter accuracy.

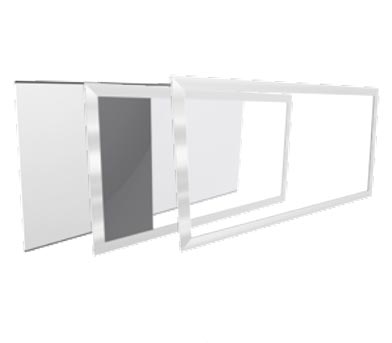

The shaft is constructed on the basis of an anodised aluminum frame interconnected with a panel type to your perference. The multi-layered powdercoated sandwich panels or laminated glass panels come as standard selections and can be mixed and matched to suit.

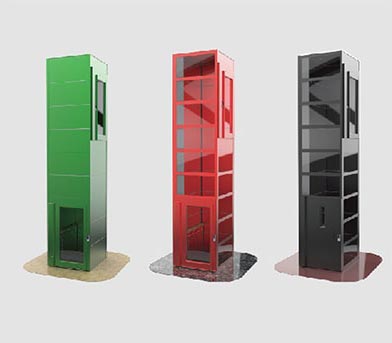

“This type of construction looks aesthetic and modern and gives a clear view of the surroundings.” A maximum of three doors may be installed on each floor with either left or right swing. By request , the platform and panels may be painted in any color of the European RAL range.

Flex-e Lift is a standard color RAL9006 (white aluminum) and anodised aluminium.

Application

Flex-e Lift is designed for use by all types of passengers, including the elderly and people with limited mobility.

Able to be fitted in both interior and exterior locations for new and existing buildings.

Flex-e DDA Lift has all the essential qualities of a platform lift:

- Compact overall dimensions

- Low 50mm pit or no pit (50mm entry ramp)

- No machine room or external cabinets

- Quiet operation

- Low energy consumption

Flex-e Lift is often installed in schools, offices, libraries, museums and other public areas requiring compliant access with occasional use.

Durable, adaptable and fully compliant with NCC E3.6 for heights of up to 4m as a “Low rise, low speed constant pressure lift – enclosed type”.

Innovation

Flex-e DDA commercial lift combines timetested design solutions and new approaches to electronic control and fault diagnosis. By using the highest quality materials and components, our task is to increase the longevity of the lift and to minimize the downtime associated with troubleshooting and maintenance. The elevator control system can be equipped with a special diagnostic module that provides the detailed information on the status of all platform nodes and system sensors. The module informs about the usage of Flex-e, including the number of lifts and trip distances.

It also enables to perform the adjustments on the lift operating settings, including speed and smoothness, the height of stops, lock closing time, button modes and much more. With a sufficient expertise of staff a computer may be used instead of a module to implement the modifications and even reprogram the system completely. The diagnostic module helps to perform the functions of the remote monitoring, voice messaging and two-way wireless speakerphone via GSM.

Cost efficiency

The maximum efficiency of Flex-e commercial lift is achieved by using lighter materials, power saving lighting technologies and selecting a specific electric drive. The electric drive of the lift is constructed on the basis of an electronic frequency converter, which has the best characteristics of power consumption compared to directly connected motors, and enables the adjustment of the speed and smoothness of movement.

Lifts come with either a three-phase or single-phase frequency converter, depending on the capabilities of the present electrical circuit and intensiveness of lift usage. The frequency converter always provides the engine with the most optimal energy supply and prevents any energy wastage at the same time adapting to the grid voltage drops.

Comfort

The absence of the lift cabin in Flex-E lets us make a spacious and light platform. A standard platform (1400 x 1100 mm) ensures a comfortable journey for a person with a wheelchair and his attendant. The control of the platform is very simple and intuitive, with a stable system to incorrect commands or its subsequences. A passenger may stop and resume the movement at any time of the trip and even change the lift’s moving direction.

The beginning and the ending of the lifting process are performed in very smooth easing algorithms and don’t evoke any uncomfortable feelings for sensitive people. A uniformly backlit control panel, with a comfortable handle below, contains large buttons with embossed symbols at a convenient height for accessing from sitting or standing positions.

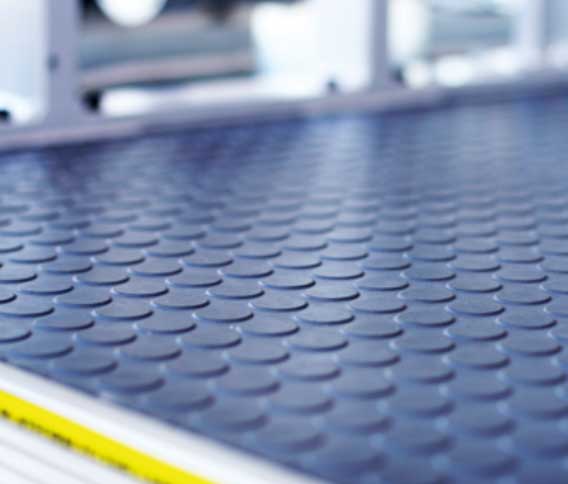

Platform Floor

The platform floor cover is made of rough antiskid material, which is highly adhesive and abrasion resistant. The floor coating material may contain logos, promotional materials or pictures according to our clients’ needs.

Led lightning

We use the latest LED technology for lighting of Flex-e commercial lift as it is cost-effective, durable and has a wide palette range. The sets of a large number of LED elements provide uniform illumination and an excellent aesthetic appearance. Energy saving LED lighting may stay on for a long time even in case of an emergency power failure. A backup battery installed on the platform may keep the necessary level of lighting for a couple of hours.

Reliability & security

Flex-e commericla lift is continuously improving its vertical screw driven platform in terms of security and reliability indexes. The product reliability is the feature which is beneficial to both consumers and manufacturers. Long time testing has shown that even after 50.000 cycles and more than 600.000 meters of travel the amortization of the main gear was hardly recognizable. The control system of Flex-e lift has passed stringent tests on the impact of the strong external electrical interference and received a certificate of electromagnetic compatibility (EMC). Technical maintenance service performed a general analysis on the lift design and its schematic solutions, in order to identify any possible weaknesses in security, and came to the conclusion. Berduva is the sole manufacturer of Flex-e commercial lift based in Europe.

Conclusion

Conclusion that all measures are fully implemented, confirming the certificate of conformity. The security measures implemented in the Flex-E DDA, comply with

one of the most stringent European standard EN81-41: 2010.

Flex-E DDA always fixes itself at an exact indicated position thanks to the triple braking torque system:

- Self braking torque of a nut and a screw;

- Electromechanical brake inside the motor;

- Electromechanical brake on the nut, executed by powerful solenoids.

In case of emergency situations the lift mechanism is supplied with a manual emergency descent. Optionally, the emergency lowering mechanism may be actuated by an electric motor with a backup battery.

Full view of Flex-E DDA lift

See the images from inside and platform looks of Flex-E commercial lift

Features & benefits

- Compliant up to 4000mm travel under – NCC2016 E3.6 & AS 1735.12

- Modern aesthetics – Aluminum frame with 10mm laminated glass cladding that can enable a panoramic view for the user. Frame can also be ordered in any custom colours

- Low construction preparation – it includes its own self supporting aluminum frame which removes the construction costs of having to build a masonry lift shaft

- Smooth operation – Electrically operated, the Flex-e will gently transport the user between floors

- Installation flexibility – Lift is able to be assembled onsite meaning it is able to be fitted into tight indoor locations

- Either a 50mm pit or a small entry ramp can be included

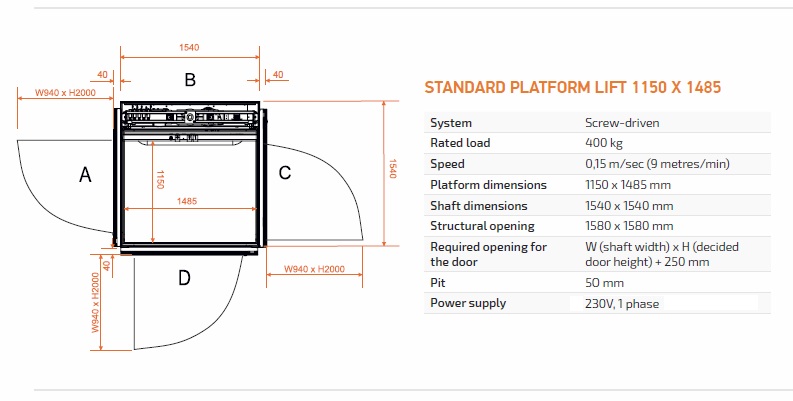

- 1485 x 1150mm Platform size

- Emergency lowering

- Battery backup

- Emergency autodialer

- Key On/Off on control panel

- Controls on both sides for left or right handed use.

- Braille on buttons available

- Available with or without automatic doorways

- Audible floor notifications

- Landing and cabin displays to show direction of travel and current floor

- 400kg Capacity

Add-Ons

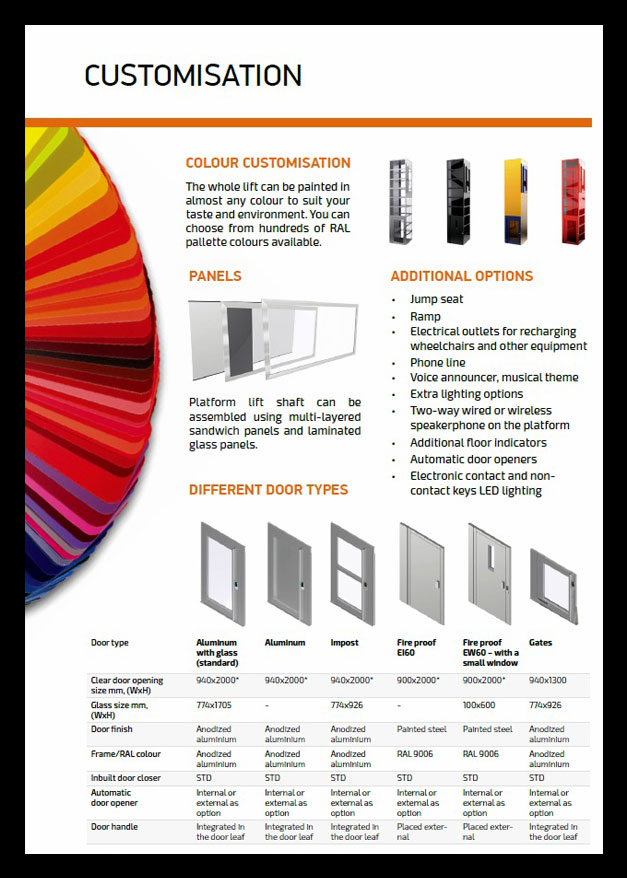

Colours customisation

The complete lift can be painted in almost any colour to suit your taste and environment. You can choose from the hundreds of RAL colours available.

Panels

Platform lift shaft can be assembled using multi-layered sandwich panels and laminated glass panels.

Different door types

Additional Options

- Automatic door openers

- Additional floor indicators

- LED lighting

- Extra lighting options

- Voice announcer, musical theme

- Jump seat

- Ramp

- Electrical outlets for recharging wheelchairs and other equipment

- Two-way wired or wireless speakerphone on the platform

- Electronic contact and noncontact keys

- Remote control

Gallery

| Feature | Specifications |

|---|---|

| Rate load | Up to 400kg and more |

| Capacity | Up to 5 persons |

| Drive system | Screw driven |

| Power supply | 220-230V, 1phase |

| Motor | Up to 3 kW and more |

| Frequency converter | Soft start - soft stop comes as a standard |

| Travel height | Up to 13 metres |

| Landings | up to 6 |

| Platform dimensions | 1100 x 1400 1070 x 1485 1150 x 1485 or 1100 x 1400 (lenght x width, mm) |

| Shaft Dimensions | 1460 x 1540 or 1540 x 1540 or 1500 x 1540 (lenght x width, mm) |

| Door clearance | 940 x 2000 (width x height, mm) |

| Gate | 940 x 1300 (width x height, mm) |

| Door configurations | Right or left swing, up to 3 doors per landing |

| Shaft walls | Aluminium profiles with glass or steel panels |

| Standard colors | RAL 9010 (pure white) RAL 9006 (light grey aluminum) *any RAL color available as option |

| Soft start/stop | Comes as a standard |

| Power supply | 220-230 V, 1 phase, 40A; 380-400 V, 3 phase, 25A, 50 or 60 Hz |

| Motor | 2.2kw |

| Noise level | Less than 70 dB |

| Control system | Micro computer based |

| technical safety equipment | Safety edge around the the platform, emergency STOP buttons, electronic speed control, overload detector, opening control of doors and locks, electronic control of engine performance |

A closer look at a few of our Flex-e commercial lift projects.

our Flex-e DDA range will integrate seamlessly with almost any commercial space, without extensive requirements. check out some of our exclusive installations and get inspired!.